Bids Is

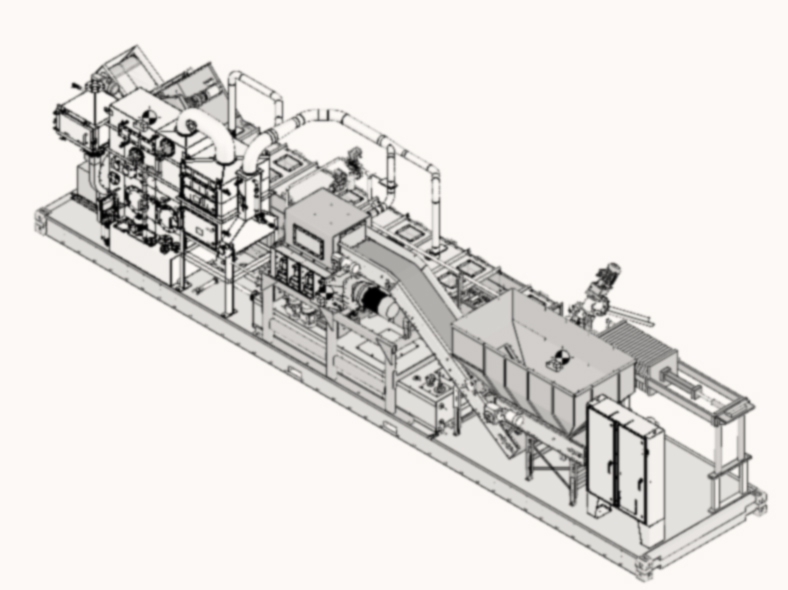

The first to market battery-in-device and battery shredding unit designed for individual warehouse applications. It is compact, easy to install, simple to operate, and will manage the typical volume of hard-to-manage items generated by most sites.

The system is delivered to your warehouse in a ‘plug and play’ configuration. Connect to power supply, add water, and you are ready to start processing batteries and battery containing devices. An easy to use variable speed feed hopper loads an aqueous shredder with screen. Feed stock is mechanically separated into a plastic fraction, metal fraction, and black mass. A wet scrubber ensures zero emissions and no need for external emission permitting.

How it works

What Goes In

Most Batteries

Electronic Devices

Consumer Returns

BIDS23

What Comes Out

Plastic Fraction

Metal Fraction

Ferrous / Non-Ferrous

Black Mass

Core Features

- Manage your hard to process material in-house

- Reduce labor costs

- Reduce thermal incidents

- Minimal spaces requirement

- No battery removal required

- Simple Installation

- Reduce long-term storage

- Ownership of Out-Put Commodities

- Affordable CAPEX

designed for

E-waste collectors/

processors

Battery

Recyclers

OEMs

Contract

Manufactures

FAQ

Can you put a battery containing device (like an e-cigarette or cell phone or ear pod) into the system?

Yes, the system is designed to manage loose batteries and batteries in devices (up to the size of a laptop).

Can all batteries be shredded in the system?

No. Nickel Cadmium and Lead batteries, and devices containing Nickel Cadmium and Lead batteries should not be charged into the system. All other common consumer battery chemistries can be processed.

What about the hazards associated with lithium batteries?

This system is the only warehouse-based system specifically designed for managing the localized hazards related to lithium-ion batteries. The aqueous shredder is built to shred all chemistries of lithium batteries.

Can I shred EV car batteries?

The BIDS system is not designed for large format batteries. However, some EV pack modules may be managed by the system. Please consult your sales representative.

What about the hazards associated with lithium batteries?

This system is the only warehouse-based system specifically designed for managing the localized hazards related to lithium-ion batteries. The aqueous shredder is built to shred all chemistries of lithium batteries.